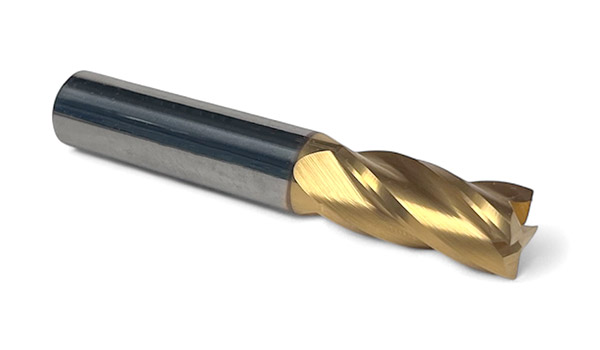

A general-purpose, low-cost point, gold colored coating that allows for higher metal removal rates and extended tool life compared to uncoated tools.

A lubricious coating and with proper post treatment it is useful in stamping, forming and tapping operations, as well as the machining of non-ferrous materials. While great for many metals, it may not perform as well when cutting very hard or heat-resistant materials. Also, is not recommended for dry machining.

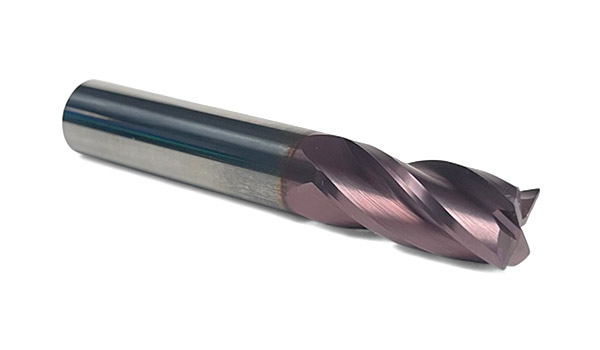

The most popular coating, AlTiN is an abrasion resistant, cathodic arc deposited coating. Excellent for high metal removal rate machining. Recommended for the machining of cast iron, hardened die steels up to HRc 45 and other heat-resistant alloys. AlTiN also has a low friction coefficient which reduces friction between the tool and work material, enhancing the tool’s lifespan and performance.

With excellent thermal stability, Alcrona can withstand high temperatures, maintaining performance and protective qualities at temperatures up to 1100°C (2012°F). This property makes it suitable for high-speed machining and dry cutting. The coating reduces friction between the tool and work material, improving efficiency and minimizing heat buildup. Ideal for metals that are between 42 and 50 Rc.

High thermal stresses result in high abrasion, increased risk of chipping and formation of cracks on cutting tools, which shortens tool service life and reduces productivity. To meet these challenging machining demands, Talon coating is the high performance coating that you need. Talon coating is recommended on tools that are employed in high-speed machining, particularly in hard-to-machine materials like hardened steels and high-alloy metals.

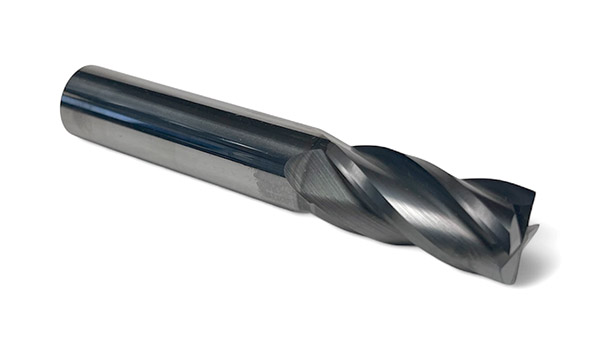

One of the hardest coatings with a low coefficient of friction, recommended for high silicon aluminum alloys, titanium alloys, magnesium alloys, no lead brass, bronze and copper alloys.

HDT is a highly advanced TiAlSiN PVD coating that is engineered to perform in a diverse range of applications. Ideal for any cutting tool that is used in high-speed machining of hard-to-cut materials such as hardened steels, nickel-based superalloys, and titanium alloys. HDT is exceptional for applications requiring high material removal rates by providing excellent wear resistance and high thermal resistance. Its thermal stability and low friction properties can reduce or eliminate the need for cutting fluids, which can simplify operations and decrease costs.

Latuma PVD coating is an advanced type of physical vapor deposition coating known for its excellent performance in high-wear and high-temperature applications. The ability to maintain performance at high cutting speeds allows for more efficient machining and reduced cycle times. Ideal for applications over 50 Rc.